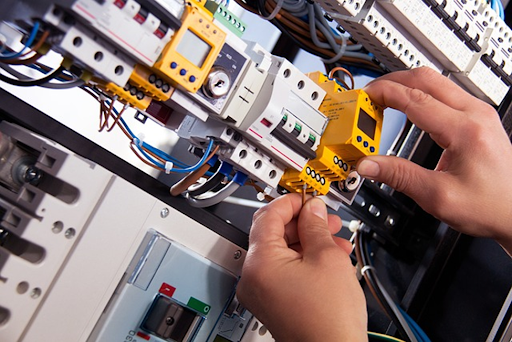

Having an effective wire marking system can wind up paying dividends in more ways than you realize. It might seem simple, but knowing which cables and wires go where can wind up saving a lot of time and money in the process.

If you aren’t sure how to choose a cable marker, you’re in luck. There are a few considerations to make when choosing a cable labeling tool to make your next installation a smooth one.

Marker Types

There are plenty of considerations to make but consider the type of cable marker you need. There are plenty of cable markers to choose from when shopping with a vendor like RS, but you can save yourself a lot of time and narrow the search down exponentially by having a good idea of what type of cable marker you want.

Are you looking for something temporary? Adhesive? How much information do you need to display? When you have essential information like that, any technological installation can become simpler. With wrap-around markers, rotating wire labels, sleeves, tags, and flags, there is the optimal cable marker to suit your application and installation.

Durability is Important

While there are more than a few considerations to be made, durability is right up at the top of the list. These labels or markers need to be able to stand up to regular movement and friction. After all, it defeats the purpose of having cable markers if they are just going to wear down and fall off.

Choose cable markers that are able to hold up over the long term. You will also need to consider whether these markers will come into contact with chemicals, solvents, water, or oil, things that can compromise the ability of wire markers to do their job. Durability is especially important if you have to keep things like special requirements or even government specifications in mind.

Marker Location

There are two important considerations to make when selecting wire markers. Let’s look at markers for before and after termination.

Before termination. Wire marker sleeves have to be slipped over the open end of a wire, which means that they can only be used before termination. These tend to be non-adhesive markers that offer greater flexibility. They can also be moved before any heat shrinking is applied. After these markers have been heat-shrunk, they provide a permanent marker that will hold up against most harsh environments.

After termination. There are both wrap-around and self-laminating wire markers. These can be used both before and after termination. For wrap-around markers, the legend will be visible from all sides since it is completely wrapped around the wire. For self-laminating markers, there is a clear part of the label that will wrap around and laminate that legend, keeping it safe from moisture or scratches.

Gauge Size

You can’t get the proper cable marker if you don’t have the right gauge size. With the right fit, cable markers will remain snug while also protecting the information being displayed. There are a few tips to help you cut down your choices.

Any sleeves should be at least twice the height of the diameter of the cable. Self-laminating should be +/- 6,5 times the diameter while wrap-around markers should be +/- 3, 5 times the diameter. If you are dealing with thick wires, make sure that you are using straps as well as a wire bundle tag. Knowing the gauge of wire you are dealing with can help you make the proper pick and ensure that the labels remain intact for a long time.